Bespoke infrared heating solutions for automotive applications

Ceramicx has always worked closely with the automotive industry, seeking to provide the accurate temperature control and increased efficiency of infrared heating solutions needed across a range of materials and processes.

Because of the extent of materials used in automotive applications, infrared heating is an increasingly trusted and sought after solution. When temperature control and accuracy is critical, we work with our partners to provide a complete service. Custom heater shapes, allow the production environment to be accurate, efficient, and fast regardless of the convoluted nature of the material.

Learn about some infrared heating solutions for the Automotive industry that we have developed –

-

Bonding Automotive Interiors

Learn moreOne of the biggest US automotive companies were looking for a more automated solution to their production process. Their Tier 1 supplier made contact with our business partner in the United States, Weco International.

-

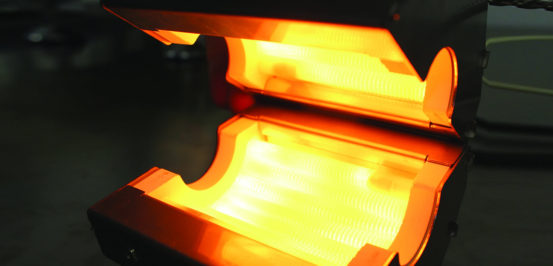

Contract Manufacturing: Heatshrink Application

Learn moreWith two infrared heat solutions needed, both had strict specifications in terms of power, temperature, dimensions, and reliability, and both were developed using our infrared quartz heating elements. The clamshell shape was a natural consideration and Ceramicx worked on this using quartz infrared elements components.

-

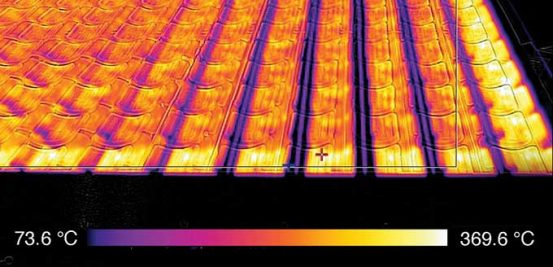

Cut-Sheet Thermoforming Oven

Learn moreA UK based Tier 1 automotive supplier were having some productivity issues. Specifically, they were looking for uniformity of heat to ensure repeatability and consistency of product. They wanted to upgrade their current infrared heating system which consisted of large upper and lower panels.

-

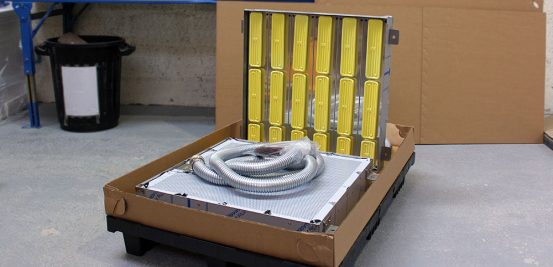

Heat-Shrinking Test Unit For Automotive Sector

Learn moreTo improve an inefficient and slow manual system, Ceramicx were given the green light to design and build a standalone, multi-zone, infrared heating test unit. Using a series of SFEH 600W ceramic infrared heating elements, the system is custom-designed to give a faster process, with more efficiency and consistency in the heat-shrinking of plastic and textile cloth wrapping for rigid rubber tubing.

-

Quartz And Ceramic Infrared Heating Systems For OEM Industry Leader

Learn moreUsing a mix of quartz and ceramic trough infrared elements, the new stand alone IR systems would bring efficiency and speed to their processes.