- About

- Heating Solutions

-

-

- Heating Solutions

- Ceramicx has the in-house capabilities to build custom-designed industrial infrared ovens and heating solutions to almost any design and specification.

-

- Control Systems

- By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that meet every requirement.

-

-

-

- Retrofits, Rebuilds & Upgrades

- Information

-

-

-

Latest Blog

St Patricks Day 2023

Happy St Patricks Day 2023 to all our Customers, Suppliers, Employees and Friends. St. Patrick’s Day, Friday 17th March is ... Read moreSt Patricks Day 2023

-

-

- Industries

- Enquiries

- Contact us

- Ceramicx Components

Infrared Thermoforming Ovens

Home Heating Solutions Oven Process Infrared Thermoforming Ovens

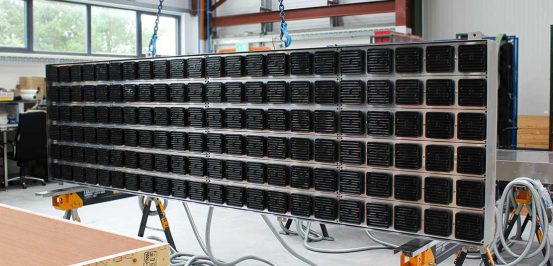

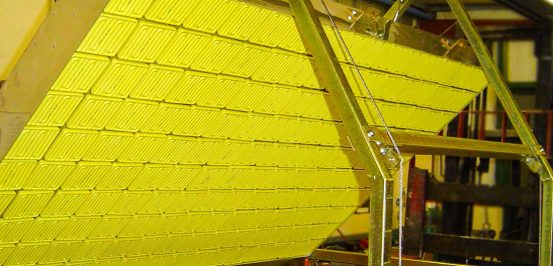

As specialists in infrared heating solutions, custom-designed industrial infrared thermoforming heating systems from Ceramicx are manufactured to the exact specifications and requirements of each customer. With precision configurations for increased thermoforming line efficiency, lower power consumption, and better forming, our engineers have the infrared technology for a bespoke, total heat solution. Materials we have worked with previously include ABS, PE, PS and PET.

Designed and built to your exact specifications and process requirements with full CE approval, a Ceramicx industrial thermoforming heating system provides the accuracy and repeatability you need for any sheet thermoforming processes, including vacuum forming.

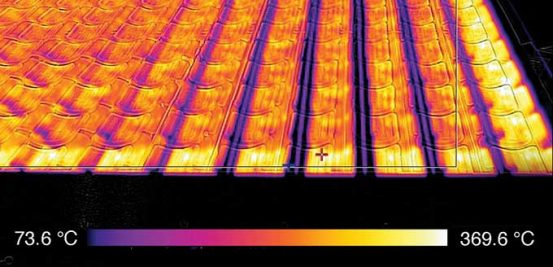

Using the latest infrared heating technology and precision multi-zone heating control systems, every thermoforming oven is the ideal heating solution for any high output application. For full consistency in product quality, the upper and lower heating panels can also consist of two different element types.

Drawing on our extensive heatwork experience, a custom-designed Ceramicx heating system for your thermoforming oven is fabricated for your own unique processes. Using stainless steel inner frameworks for maximum reliability and durability, arrays of high quality Ceramicx infrared elements and polished aluminium reflectors give the balanced heat distribution needed to heat and shape your specified polymeric material.

Our design and engineering team also integrate the latest in heat control systems. Fully programmed and easy to use, they provide ultimate precision in speed, timing, and temperature control for your applications. As a complete standalone system or with the ability to integrate with existing machinery, the flexibility of design provides you with a completely bespoke heating and control solution, including.

Industrial Infrared Thermoforming Heating System

-

Bonding Automotive Interiors

Learn moreOne of the biggest US automotive companies were looking for a more automated solution to their production process. Their Tier 1 supplier made contact with our business partner in the United States, Weco International.

-

Cut-Sheet Thermoforming Oven

Learn moreA UK based Tier 1 automotive supplier were having some productivity issues. Specifically, they were looking for uniformity of heat to ensure repeatability and consistency of product. They wanted to upgrade their current infrared heating system which consisted of large upper and lower panels.

-

In-Line Thermoforming Oven Solution

Learn moreThe UK based company called Linpac Packaging provides rigid and flexible packaging solutions to customers around the world. They approached Ceramicx to design and build a new heating system that could integrate into their current machine.

-

Multi-Zone, Infrared Thermoforming Oven For Manufacturing

Learn moreAlready using an older system, with gas catalytic infrared emitters, the biggest concern for the customer had been issues with the zoning of their emitters and the uneven and inconsistent temperatures. The challenge was to create a custom-designed, replacement infrared thermoforming oven that gave more comprehensive sheet heating through multi-zoning.

-

Santa Fe custom skylights

Learn moreCeramicx were tasked to upgrade an ageing and energy-costing plastics thermoforming line to an infrared-based solution – while remaining well within the power constraints for the local electricity grid.

-

Thermoforming System Upgrade for Insulation Provider

Learn moreSupplying the construction industry with a comprehensive range of insulation materials, the need for quality and efficiency led Xtratherm to choose Ceramicx for a more reliable and effective custom-built system.

-

Upgrading Food Packaging Thermoforming Lines

Learn moreThe client required a complete upgrade on one of its main plastics thermoforming lines – manufacturing consumables for the food service industries. The project scope included removal of the existing oven and replacement of it with an efficient ceramic-based top and bottom panel heater infrared oven.

-

Vacuum Forming Oven

Learn moreA major Canadian company that makes hot tubs, contacted our distributor in the United States to help them build one section of their machine. They were in process of building a machine to mould hot tubs and they wanted us to do the heat work for the section of their vacuum forming machine.

Bespoke manufacture, design and build

- Mounting brackets and wheels for easy lifting and moving

- Extra structural protection and features for easy shipping and partial re-assembly

- Specialist insulation, steel meshing, rotary wheels, and viewing windows

- Removable, perforated steel backing for access

- Multiple doors for easy access to heat chamber

- Custom safety features for your process needs together with emergency stop

- Bespoke electrical junction boxes positioning

- Full range of spare parts

Bespoke heating system and controls

- Material testing for your process

- Ceramic or Quartz elements or Quartz Halogen or Quartz Tungsten tube heaters to suit

- Modified Fast IR and Modular IRs

- Upper, lower, and vertical heating panel systems with adjustable height

- Custom heater geometry and multi-zoning with concentration of heat direction

- Custom distance and heater array

- Remote monitoring capabilities

- Complete individual custom programme control or modular system

- Element failure detection option

- Precision heating tolerance in °C/ºF

Whatever configuration you require for your composite heating system, our specialist heat engineers will custom design and build a complete and bespoke infrared heating system to your specifications. Our full ‘Project Completion’ approach gives you a comprehensive end to end service that keeps you updated through every stage of the process.

After your initial enquiry and our detailed proposal, we can provide detailed photos of progress if required – from materials testing and R&D to the functional design specification (FDS) and 3D CAD/CAM design, to product testing and final manufacture.

Solution Testing

This is your system, designed and built by us to your specifications and we undertake detailed and thorough system testing at every stage. Our ceramic and quartz infrared heating elements have detailed end of line test results and performance data to confirm correct operation.

To ensure we exceed your expectations, as well as maintaining our own high standards and quality control, we encourage your full customer feedback. Together with our ongoing customer support – even after your system has been installed – your total satisfaction in every area is what we always set out to achieve. We continue this after sales service by providing spare elements as well as further infrared oven design and builds if you choose to expand your order with us.

YOUR NEXT STEPS

At Ceramicx, we have the in-house capabilities to build custom industrial infrared ovens and heating solutions to almost any design and specification. Whatever your requirements, we’ll give you the clarity and advice you need to design and build a high quality, infrared heating solution that meets your needs.

Call our technical team today on +353 28 37510 or email on [email protected]. We’ll be more than happy to discuss potential solutions and answer all your questions so you can make an informed decision.

We look forward to hearing from you

Get in touch with one of our infrared heating experts