With our varied infrared heat work in the automotive industry, I’m reminded that generic technology often needs a specific industrial setting before it can become more widespread and universal.

With our varied infrared heat work in the automotive industry, I’m reminded that generic technology often needs a specific industrial setting before it can become more widespread and universal.

As a case in point, the work we carried out on our custom-built Ceramicx clam shell IR heater probably wouldn’t have taken place without prior, intensive heat work with Automotive Tier 1 supplier, Mecalbi.

Infrared innovation

The design and engineering of today’s cars contains miles of wiring and more electronics than ever. The technical term for this is ‘harnessing’, and Portugese-based company, Mecalbi, helps make plenty of it via the machines it supplies worldwide.

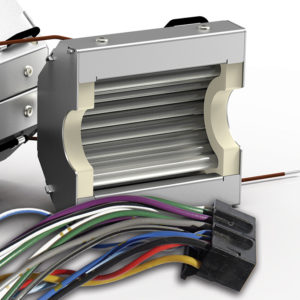

Founded in 2006, Mecalbi are global heat shrink specialists and produce machinery that can heat shrink thermoplastic sleeves around a variety of automotive wiring. As Mecalbi looked to perfect their heating and drying process cycles, Ceramicx stepped in to design and build a custom clamshell infrared heater that would be fitted into each machine they produce.

Harnessing the opportunity

This heat work method proved so effective for Mecalbi that Ceramicx has now gone on to design other innovative, large scale clam shell heaters/ovens which we now market under our own label.

It goes to show that by addressing one specific issue for one company, it can create an opportunity to design and market a generic industrial oven that helps many other companies in their own application processes.

Dr Cáthál Wilson