Bespoke infrared heating solutions for the construction industry

Infrared heating technology is changing the face of the construction industry. As a dynamic sector, the construction industry is constantly evolving, and the materials being used must develop with it.

Ceramicx infrared heating solutions have been instrumental in the design and manufacture of new kinds of innovative and weather-resistant products and materials for the construction and building industries.

The role of infrared heat in multi-material bonding is key for applications in industry and domestic environments. From new kinds of plastic and metal pipework to process plant machinery for places and situations of extreme temperature, Ceramicx can provide solutions that work, even in the most aggressive and demanding of environments.

Learn about some infrared heating solutions for the Construction & Built Environment industry that we have developed –

-

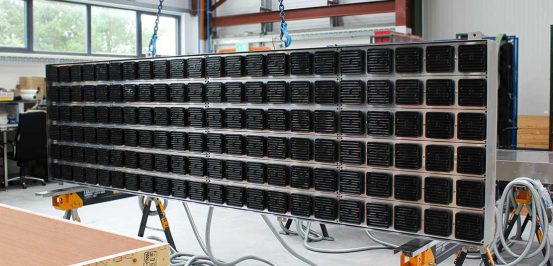

Ceramic Infrared Panels for a Consistent Drying Process

Learn moreTo keep their current processes up to date, the customer needed specialist panels to ensure a consistent heat coverage that would match previous iterations of their older and outdated heaters.

-

Multi-Zone, Infrared Thermoforming Oven For Manufacturing

Learn moreAlready using an older system, with gas catalytic infrared emitters, the biggest concern for the customer had been issues with the zoning of their emitters and the uneven and inconsistent temperatures. The challenge was to create a custom-designed, replacement infrared thermoforming oven that gave more comprehensive sheet heating through multi-zoning.

-

Creating Weather-Resistant Products For The Construction Industry

Learn moreCeramicx fast response, infrared modular heating technology to create innovative and weatherproof products for the construction and building industries. While giving them an increase in production speeds, the introduction of infrared has also shortened delivery times and improved the aesthetics and finish of their products.

-

Halogen Infrared Heating Sectors

Learn moreShort lead times for customers is one of the many perks of this process we pride ourselves on. These units were designed for a Norwegian customer for the offshore construction industry.

-

Thermoforming System Upgrade for Insulation Provider

Learn moreSupplying the construction industry with a comprehensive range of insulation materials, the need for quality and efficiency led Xtratherm to choose Ceramicx for a more reliable and effective custom-built system.

-

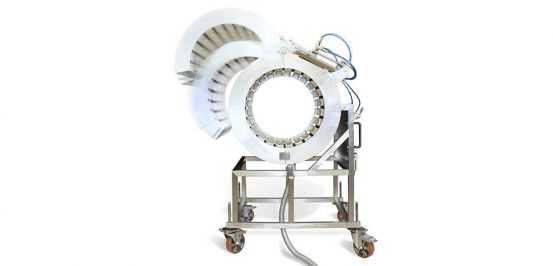

Clamshell Pipe Infrared Heating System

Learn moreCeramicx designed and built this clamshell shape heating system for a customer of one of our Danish distributers. The purpose of the shape was to heat the outside of Polypropylene pipes up to diameter of 400mm.

-

Santa Fe custom skylights

Learn moreCeramicx were tasked to upgrade an ageing and energy-costing plastics thermoforming line to an infrared-based solution – while remaining well within the power constraints for the local electricity grid.

-

Paint Curing Enclosure Design & Build

Learn moreBased near Macroom, Co Cork, Ireland, Firebird had a recent requirement to streamline and increase the throughput of its boiler production line. This was primarily needed in order to satisfy continuing demand and to circumvent seasonal bottlenecks for Firebird heating products.

-

Ceramic Infrared Heating System for PVC Pipes

Learn moreCeramicx combined all the customer’s variances and produced one heating system that could work on all the variations of PVC pipe.

-

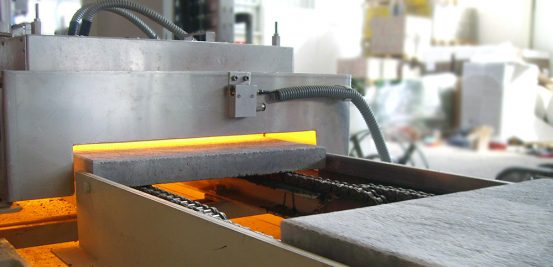

Drying System for Concrete Pipes

Learn moreFriedr-Freek and Ceramicx collaborated on the design. The decision was to provide the customer with an overall octagonal shape in stainless steel frame, with the ceramic infrared heaters facing out to the heat internal section of the pipe.