Case Study

Case study: Drying System for Concrete Pipes

A Swiss Industrial company approached our distributor in Germany, Friedr-Freek, about a drying system for concrete pipes using only infrared technology.

Friedr-Freek spoke at length with the Swiss Construction company and provided Ceramicx with clear details of what they thought would be required. The internal diameter of the pipe was 1400mm with height of 2300mm. The customer also wanted a control unit with IR temperature sensor to read the surface temperature of the concrete pipe.

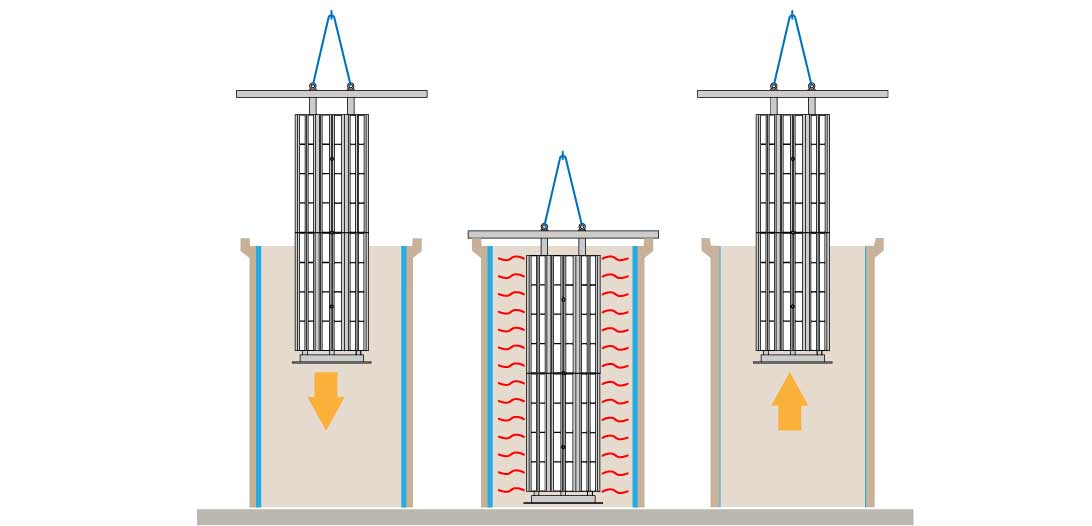

Friedr-Freek and Ceramicx collaborated on the design. The decision was to provide the customer with an overall octagonal shape in stainless steel frame, with the ceramic infrared heaters facing out to the heat internal section of the pipe. The system consisted of 3 horizontal control zones with feedback from Micro Epsilon pyrometers. During the design the customer came back to us with another inclusion in that they wanted the unit to be able to be lifted into the pipework using a crane hook. A intermediary junction box was mounted to the crane hook support.

Ceramicx built the infrared heating system from scratch, all the work was done in house from welding, fabricating, ceramic heater manufacturing, terminal block manufacturing, wiring, and building the control panel.

| Oven Frame: | Stainless Steel Box Section |

| Reflectors: | Special aluminium clad steel |

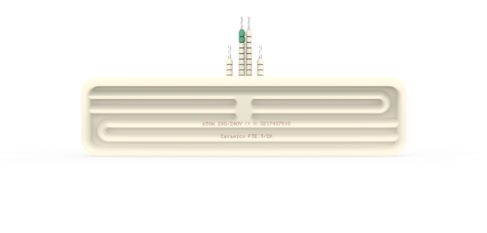

| Upper Element Type: | FTE White – long-wave ceramic infrared element |

| Controller: | KR1 Controller |

| Control feedback: | Closed loop feedback |

| Monitoring: | Pyrometer |

| Total Power: | Approx. 40Kw |

| Oven Size: | 1.4m x 2.3m |

Ceramicx tested the infrared heating system in house to ensure that the unit was properly calibrated before packing and shipping. Ceramicx also provided the system with an electrical connection via flexible metal conduit and a quick connect plug and play socket. We sent all drawings and operating documentation to the customer too. All of this ensures that Ceramicx doesn’t have to do any unnecessary commissioning of the heating system therefore providing another saving to the customer.